Doubly-Resonant Underwater Acoustic Projector for Long-Range Communications and Positioning

Carbon-fiber sound source (photo by Morozov).

The sound source was specially designed for long-range acoustic communications and potentially can be used for navigation of underwater gliders in the Arctic. A doubly resonant organ pipe provides transmission of arbitrary waveforms over a much wider frequency band. As with the single-resonance pipes, the sources can be used at all depths and are efficient and very light if built from composites. The doubly-resonant organ pipes comprise an inner resonator tube with thin walls tuned to a certain frequency surrounded by a larger-diameter tube.

The projector is driven by a monopole acoustic source attached by shock-mounts inside the inner resonator. These resonating tubes are open on both ends and typically made of aluminium or carbon-fiber. The inner tube typically has much thinner walls to allow the sound pressure to spread into the outer tube. The tubes are asymmetrically shifted along the main axis and sound pressure can penetrate from the internal pipe though the area under the shifted external pipe into that external pipe and back. By changing the length of the shifted area the coupling coefficient of two resonators can be regulated to achieve the desired bandwidth. The resulting resonant frequency is proportional to the pipe length. The radiated power from the resonators is proportional to the area of the orifices and the square of the propagated frequencies.

All ocean depth acoustic emitter (photo by Morozov).

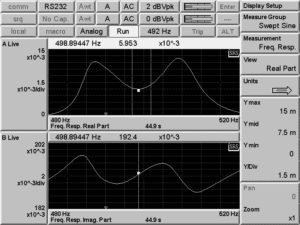

To achieve a symmetrical frequency response the radiated power from both resonators should be approximately equal. The system can be expanded to the multi-resonance, multi-frequency case with multiple coaxial pipes coupled through the shifted areas. The preliminary experiments of a doubly-resonant sound source at the Woods Hole Oceanographic Institution show that it exhibits a high electro-acoustical efficiency and a high power output over a large operating band. The WHOI US patent is pending. The frequency response is very sensitive to the resonator parameters and the resonator needs to be tested in water and adjusted according to the test results. The numerical simulation helps to predict the required parameters of the resonator and save some time necessary for fine-tuning in water.