Advanced materials for deep submergence operations

WHOI is a leader in design, construction, and operation of deep submergence vehicles such as Alvin, Jason, and REMUS 6000. These vehicles use traditional engineering materials, in particular titanium for strength and syntactic foam for buoyancy. To build the hybrid AUV/ROV Nereus, WHOI engineers determined that more advanced structural materials would be needed to reach the full depth of the ocean (11 kilometers or 7 miles), while at the same time meeting practical constraints on size and weight.

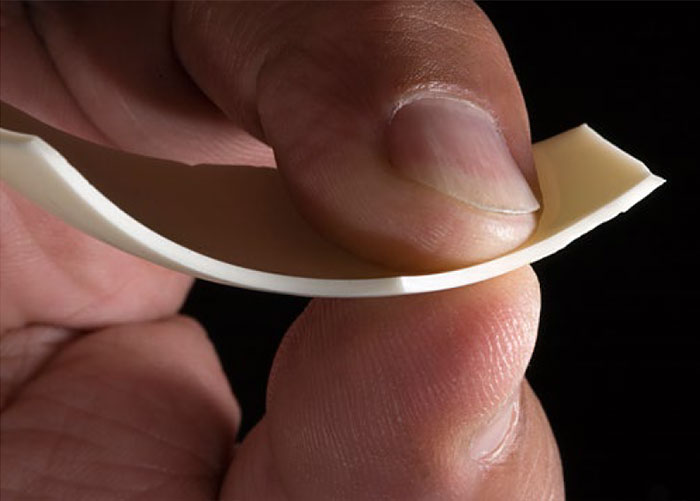

Working with colleagues from the U.S. Navy and industry, the team pioneered a new generation of one-atmosphere pressure housings to hold Nereus’ instruments, cameras, and batteries. Highly optimized ceramic spheres were chosen to provide main vehicle buoyancy. Ceramics materials have much higher strength-to-weight ratios compared to traditional deep submergence structural materials and enable Nereus to operate at the most extreme depths. For the next generation of ocean exploration systems, ceramics promise to reduce the weight required for main vehicle structure and buoyancy, leading to a significant increase vehicle payload, endurance, and capability.

Principal Engineer

Don Peters

Senior Engineer, WHOI