DunkWorks (pdf) provides WHOI and its partners with a range of useful equipment and resources to support rapid prototyping efforts, including the creation and testing of designs prior to deployment in a marine environment.

Through DunkWorks, DeepTech supports both conceptual development and physical construction by giving users of the facility an opportunity to engage in iterative design. In the process, users practice and acquire new, tangible skills to help advance their careers and the fields in which they work.

Equipment

Form 3L

Large format 3D printer that creates high-resolution objects with five times the build volume and two times the laser power of the Form 3.

MARKFORGED METALX 3D PRINTER

Metal 3D Printer and Sintering Machines capable of printing 17-4 Stainless steel, Tool Steel, Inconel 625, and Copper.

MARKFORGED MARK TWO

Continuous Fiber Composite 3D Printer capable of printing nylon and fiber reinforced composite parts

FORTUS 3D FDM PRINTER

Creates fused-deposition models from a scanned original or CAD file using ASA or nylon-impregnated carbon fiber.

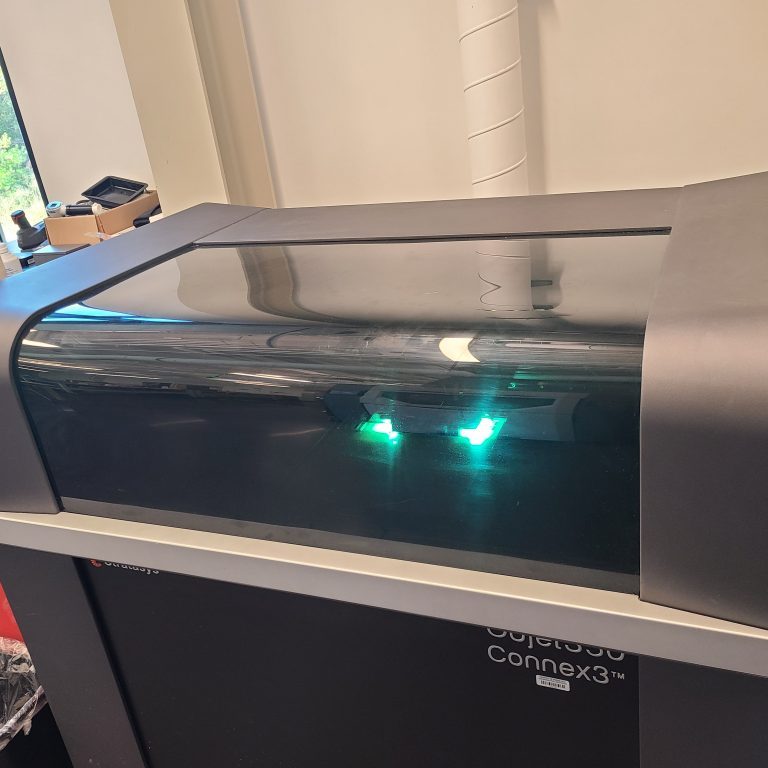

Stratasys J850 Prime

Polyjet resin 3D printer capable of seamlessly blending materials of different rigidity, transparency, or color.

Epilog Fusion M2

Dual-laser cutting and engraving system with a 40"X28" work area.

PROTOMAX WATERJET MACHINE

Cut 2D shapes from 12"x12" sheets of plastic or metal materials up to 1.5" thick

Formech Vacuum Thermoforming Station

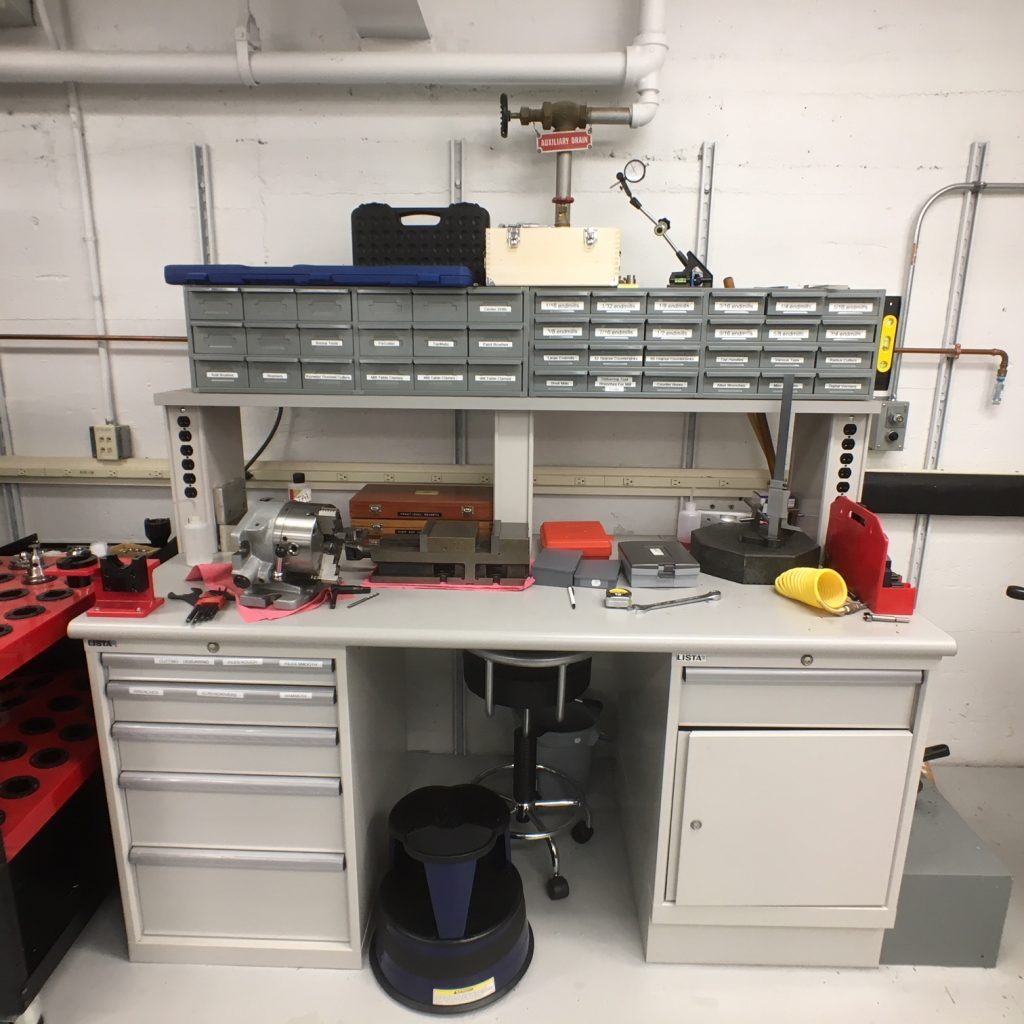

Mechanical Workstation

Includes resources for most mechanical needs, including measuring, tooling, and finishing.

Electronics Workstations

Provides regulated power supply, soldering and de-soldering tools, EM discharging, and other equipment to complete electronics projects.

COMPUTER WORKSTATIONS

Two computer workstations equipped with the software to run all Dunkworks fabrication equipment as well as Autodesk Inventor and Solidworks CAD packages for modeling.

Automated cutting, stripping, and crimping stations

Improve cable assembly workflows with precision repeatable wire stripping and connector crimping automation.