Operations

The Float Group at WHOI tests Argo floats before deployment, organizes float deployments, and collects and performs quality control checks on the resulting data.

Float preparation

The WHOI team uses floats built to Argo specifications by Marine Robotic Vehicles, performing a series of calibrations and hardware checks prior to deployment.

The Argo floats control their height in the water column by adjusting their buoyancy. This buoyancy is highly sensitive to the mass and volume of the float: a difference of just 3 grams can cause a depth error of 100 meters. Therefore, the WHOI Argo team must adjust the weight of each one so that it is exactly neutrally buoyant at 2000 dbar (pressure at 2000 meters) in the part of the ocean where it will be deployed. This process is known as ballasting.

Once hardware checks and adjustments such as these have been completed, the float is assigned a mission, or a set of instructions for sinking, rising, and measuring. GPS and Iridium communications are confirmed, and the float is packaged and shipped to the vessel of deployment.

Model of an Iridium satellite. Source: Wikipedia

Real-time data management

- Data Telemetry

- Argo floats transmit profile data each time they surface via the Iridium Satellite Network, a constellation of satellites in low earth orbit which provide global coverage for remote data communication. The data is packaged into a series of highly compressed packets which are formatted according to Argo Data Management Team standards.

- Decoding

- Data is sent to the Float Group's servers 24 hours a day. In order to promptly process this data, the WHOI Float Group has designed software capable of automated retrieval and processing of Argo float data in real-time. After the data is unpacked, a copy of the raw data is forwarded to the NOAA Atlantic Oceanographic and Meteorological Laboratory (AOML) for initial, automatic checks, and the raw data continues to undergo a series of internal quality control checks. The real-time processing system sends email alerts to the WHOI Float Group Data Management Team as critical issues with floats are detected.

Quality control and calibration of data

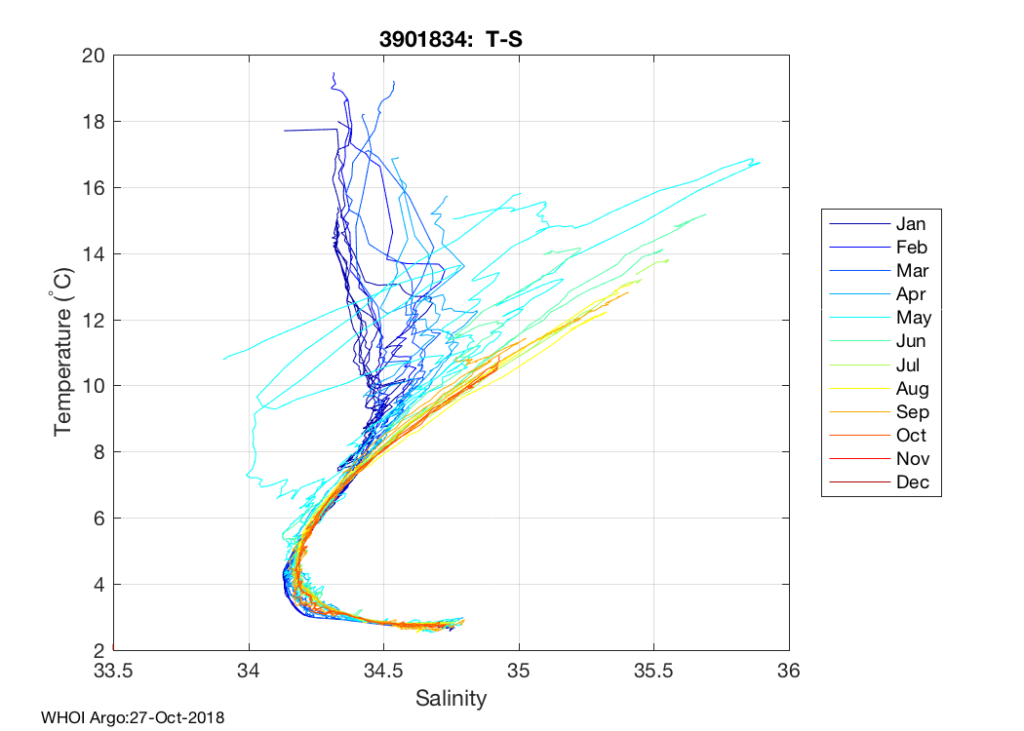

Data transmitted from Argo floats immediately undergoes an automatic quality control process before being made available online. This initial process flags a small percentage of Argo profiles as suspect. Clean, unbiased data is necessary for detecting the subtle changes in the upper ocean, and for accurately calculating heat and freshwater storage and transport. To ensure Argo data are not biased by sensor errors, every float profile is inspected and compared with nearby float and ship-based data in a process called ‘Delayed-mode Quality Control' (DMQC). Scientists in the WHOI Argo team are responsible for DMQC for WHOI-deployed floats.

Significant expertise is required to skillfully distinguish bad data from unexpected, but real, phenomena. Our staff examines temperature and salinity data for spikes or jumps that could be due to biological matter contamination or sensor malfunctions. Additionally, they check for bias in temperature and salinity by comparing them to nearby profiles from the same float and to historical data for the same area.

Additional DMQC steps include comparisons of sea height measurements with altimeter data from satellites, correction of thermal lag (due to temperature and salinity being measured at slightly different locations on the float sensor), and correction of salinity drift (salinity sensors slowly becoming uncalibrated over time) using the Owens Wong Float Salinity Calibration Tool.