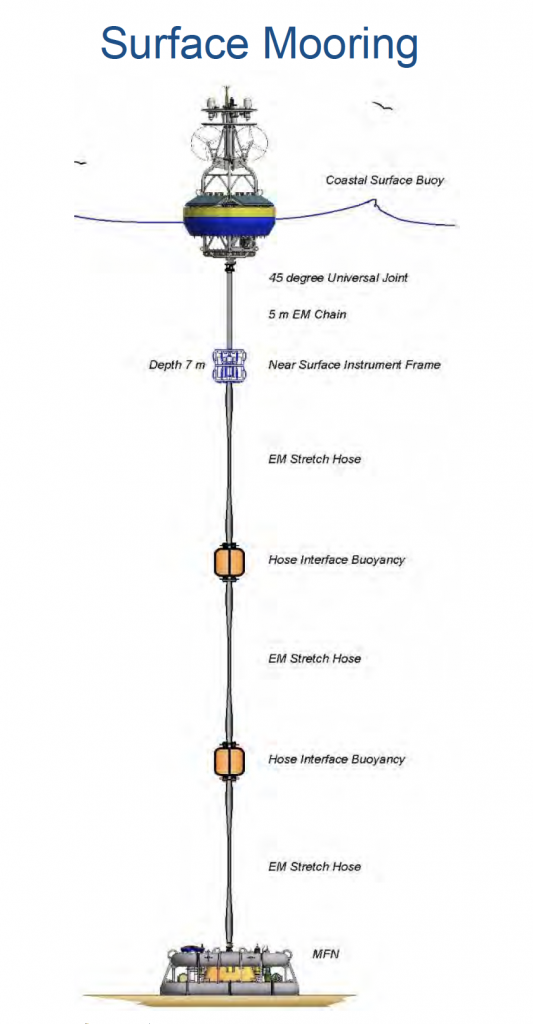

A flexible connection between the buoy and the anchor of the Coastal Surface Moorings of the Pioneer MAB Array is created by multiple hoses with the capacity to stretch while maintaining an electrical connection (Fig 1). The stretch is necessary to account for wind, waves and currents that push and pull the buoy relative to the anchor. The hoses connect mooring components and contain coiled conductors that allow data transfer and carry power generated by wind turbines and solar panels on the buoy.

Fig 1. Configuration of the Coastal Surface Mooring at the Coastal Pioneer Location at the Mid-Atlantic Bight.

The Northern Coastal Surface Mooring deployed for the first time in the MAB on April 4, 2024, illustrates the vital role these connection points play in keeping the mooring in place and operating. The mooring was deployed in 100 meters of water. The surface buoy is connected to the near surface instrument frame with a five-meter-long electromechanical chain (EM) chain. The EM Chain is flexible enough to bend to allow deployment (Fig. 2) but does not stretch. This provides support and stability at the top of the mooring. The EM chain also contains conductors to allow transmission of power created by solar, wind, and batteries on the surface mooring to the instruments below.

Fig 2. The EM Chain connects the bottom of the surface buoy to the Near Surface Instrument Frame (NSIF) to left. Credit: DT Crist © WHOI.

Closeup of EM Chain connection to surface buoy. Credit: DT Crist © WHOI.

Closeup of EM Chain connection to Near Surface Instrument Frame. Credit: DT Crist © WHOI.

Power moves through the EM chain to the instruments attached to the Near Surface Instrument Frame (NSIF), and then off to three stretch hoses each 30.48 meters long! The stretch hoses do what their name implies, stretch as needed in response to environmental conditions, yet they are strong enough to keep the mooring in place. The first section of stretch hose is connected to a Hose Interface Buoyancy (HIB) module, an orange flotation device that helps keep the stretch hoses floating and upright. The second section of stretch hose connects to a second HIB. Electrical connectivity is maintained by wired connections from the end of a stretch hose, through the hollow center of the HIB, and then to the next hose.

Two Hose Interface Buoyancy (HIBs) sections are connected to each other with electromechanical stretch houses that provide flexibility and strength to the mooring and transmit power down the line. Credit: DT Crist © WHOI.

The third stretch hose section is connected to the Multi-Function Node (MFN), which houses instruments that need power. The MFN also contains the anchor.

The Multi-Function Node and Anchor Assembly being deployed off the back deck of the R/V Neil Armstrong. The stretch hose, which connects it to the rest of the mooring, is at the top and to the right. Credit: DT Crist © WHOI.

More than 96 meters of hose keep the Coastal Pioneer Northern Array in place in its new location in the Mid-Atlantic Bight. Credit: DT Crist © WHOI.

Perspective in Pounds

What’s amazing about the hoses that keep the Pioneer moorings on station and operational is the scale of the equipment that makes up the mooring. Take the top and the bottom of the mooring, for example. The Surface Buoy weighs some 8,500 pounds. The MFN and Anchor Assembly weigh 11,000 pounds. These weights and the scale of the equipment are not only challenging for moving around the deck and getting into the water, but thanks to the hoses these massive components are able to stay in the water, collect data, and report for up to six months. Hats off to hoses galore!

Recent Updates