ITP2 Deployment Operations

The day prior to the deployment of the ITP/IMB a multiyear ice floe approximately 500 m by 500 m characterized by dirty snow was spotted from the ship, the helicopter was flown onto the floe, and two test holes were bored through the ice using a 2” diameter hand auger to determine the thickness (3.8 and 4.0 m).

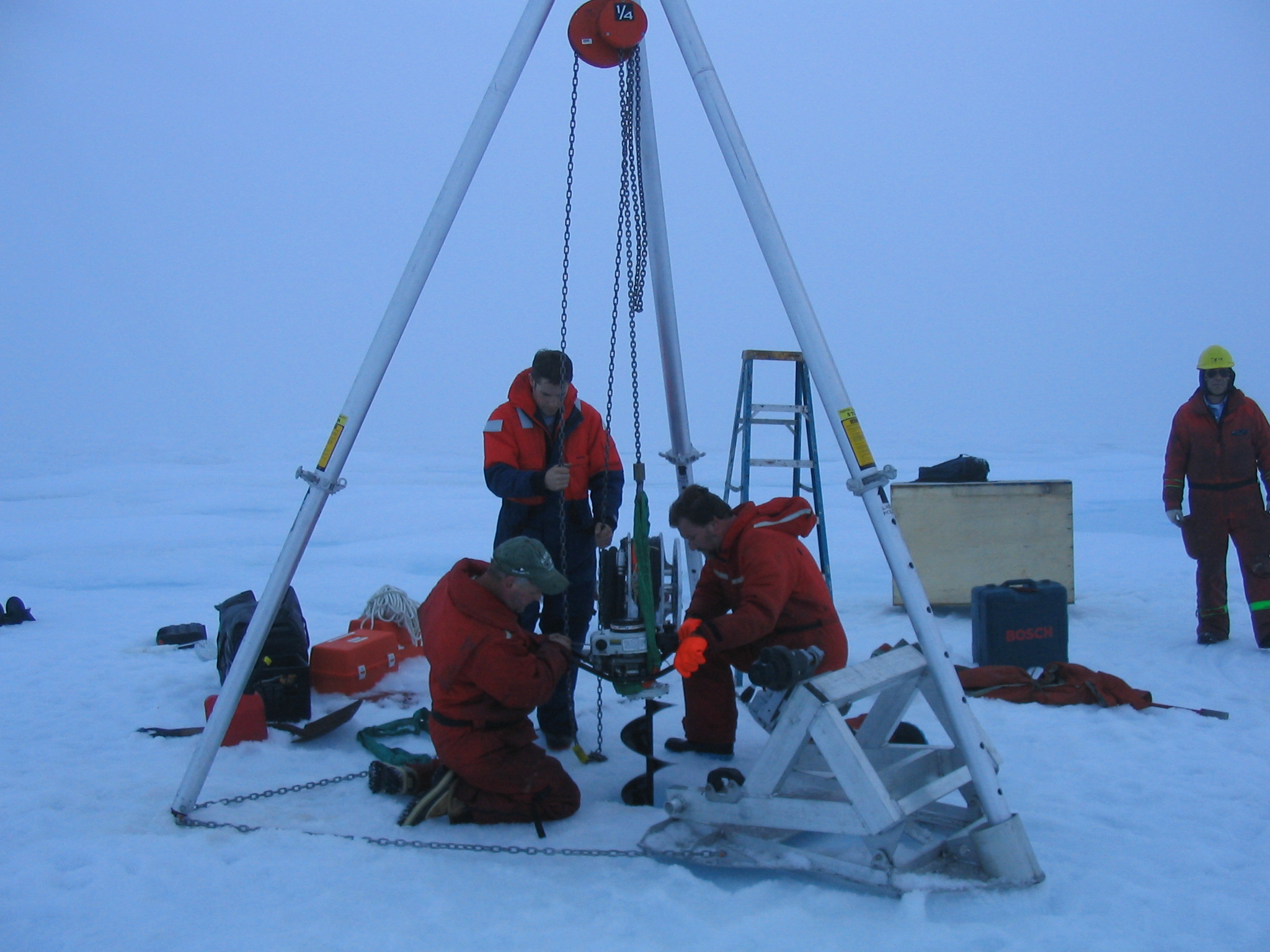

The following morning, the deployment operation began at 6 AM local time (CDT) with the transportation in light fog of an ice party of eight and all gear to the selected site in three helicopter flights and two slingloads. Drilling the 11” diameter hole through the ice for the installation of the ITP profiler was the most difficult part of the ITP deployment. Midway through the 4 m ice, the old hard ice became softer and more porous so that embedded seawater turned the ice shavings into slush, and the 10” diameter flutes had difficulty removing the material. To complete the drilling, the deployment tripod assembled and the auger hung from a chainfall, so that the drilling could proceed at a controlled rate with reduced labor.

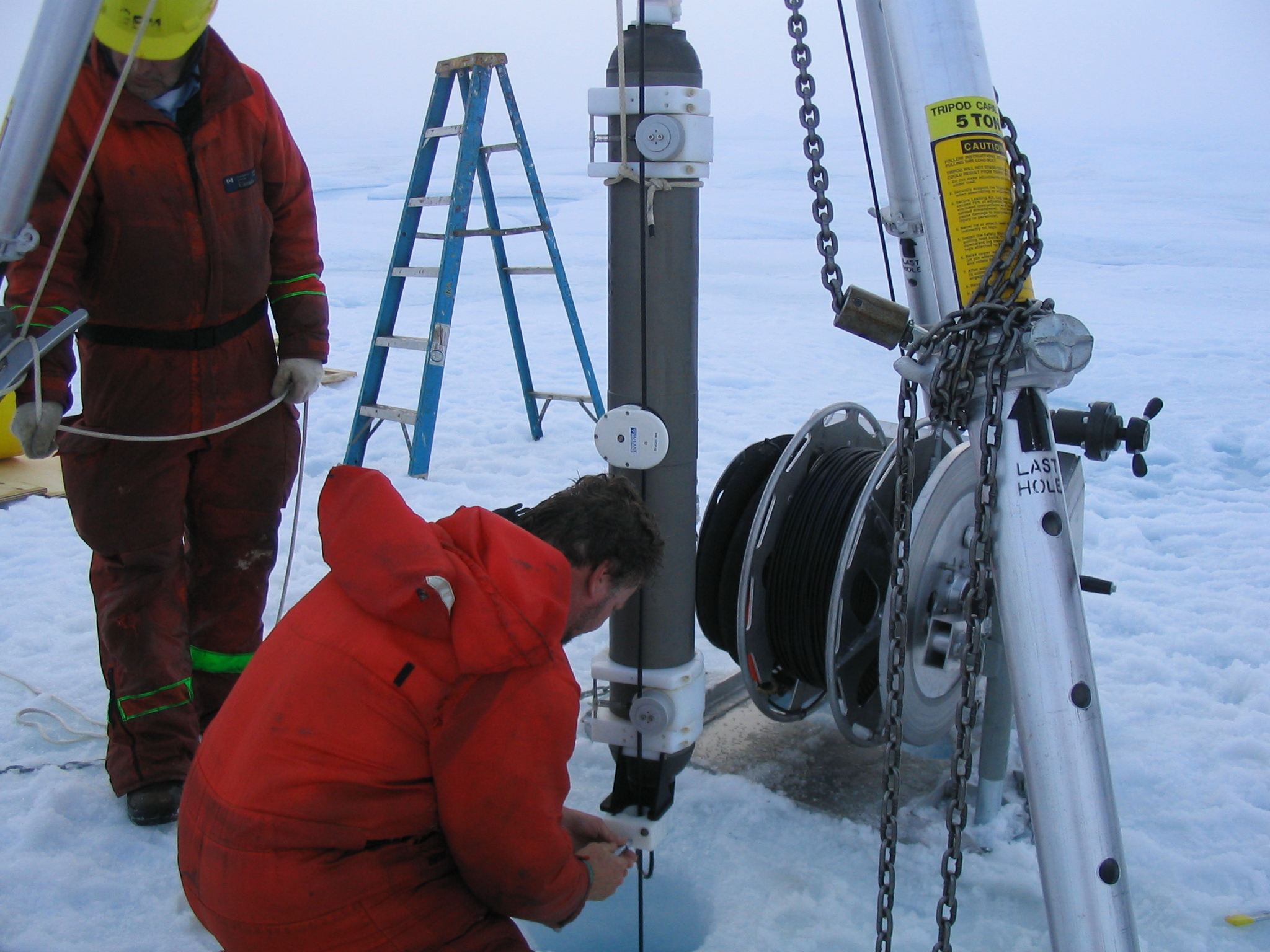

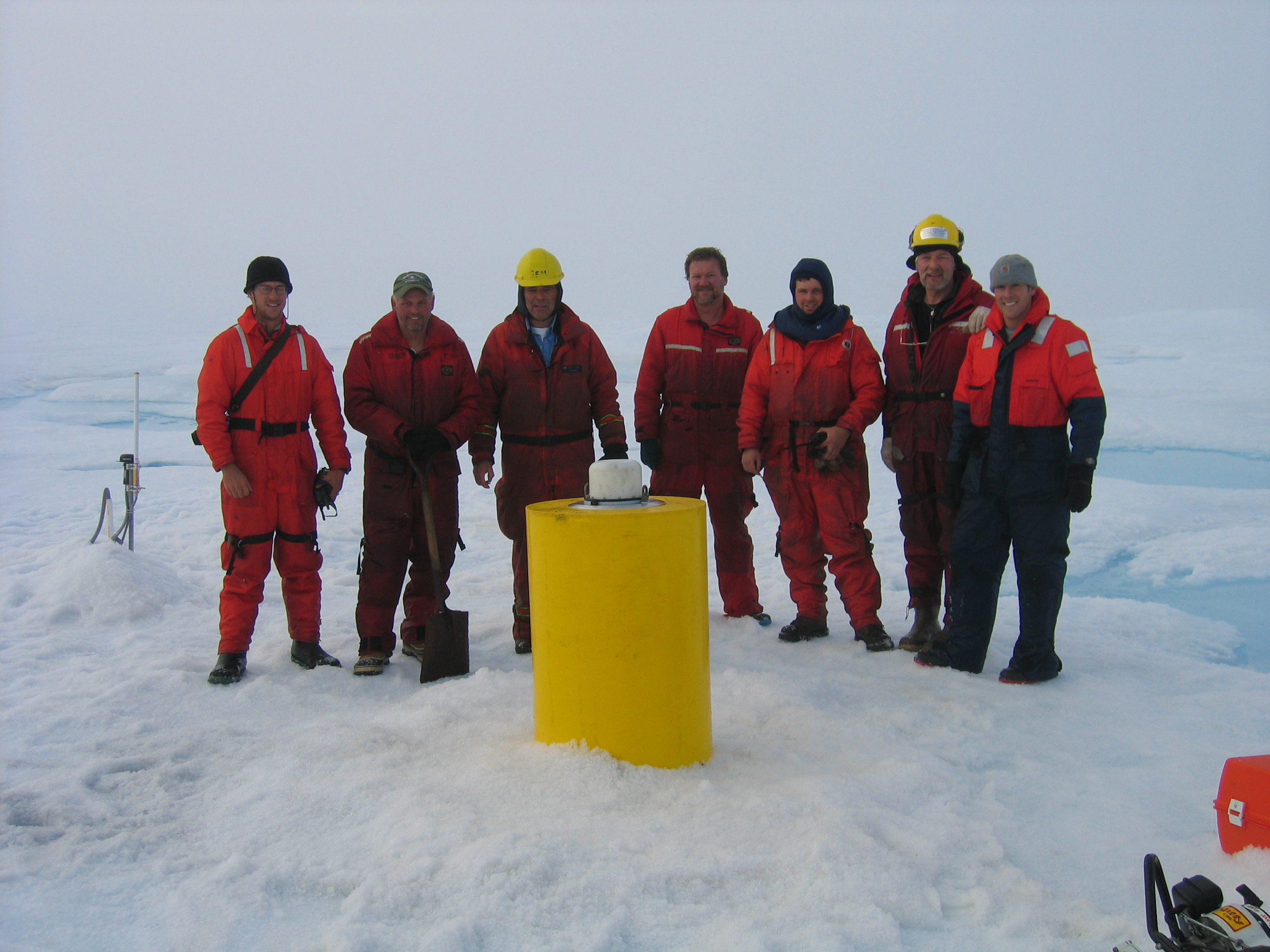

The hole was finally completely drilled by 7:30, with 50 cm of freeboard above the seawater. In the next two hours, the anchor weight and wire rope (with bottom bumper) were smoothly deployed, and then the ITP profiler was attached, and easily passed through the 11” hole, the 800 m wire rope was deployed, and the surface package attached to the tether. Subsequent communications with the underwater inductive modem through the surface package using a laptop computer confirmed that the inductive modem circuit between the profiler and surface package was operation. The surface package was situated over the hole, the tripod was removed, and a wooden platform was constructed beneath the buoy. By 10 AM local time (15:00 UTC), the ITP deployment was complete.

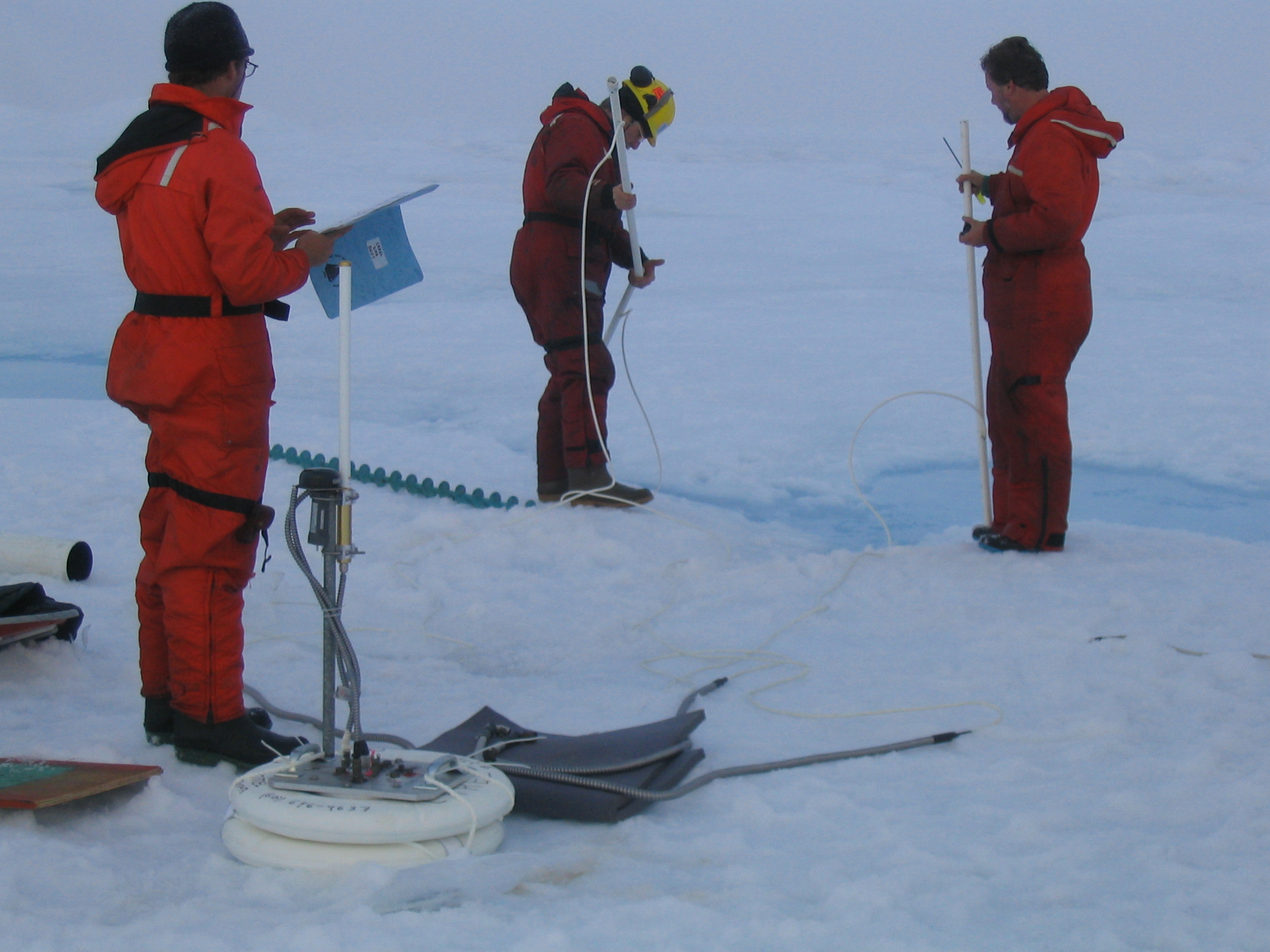

Simultaneously, the IMB was being installed approximately 10 meters away. One 11” diameter hole was drilled 1 m deep to encase the surface package, and three 4” diameter holes through the ice for the ice sensors. The thermistor hole was in 4 m thick ice with 20 cm of freeboard. Where the snow sensor was located, there was initially 5.5 cm of snow. At 10 AM, the operation of the IMB was verified using a Campbell keypad to check memory locations. Clean up and covering of the cables continued for next half hour, and all personnel and cargo were returned to the ship by 11 AM. Later, messages from shore laboratories confirmed that both buoys were operating properly.

More information and pictures of the deployment are also available here and at: https://www.whoi.edu/page.do?pid=68316.