ITP44 Deployment Operations

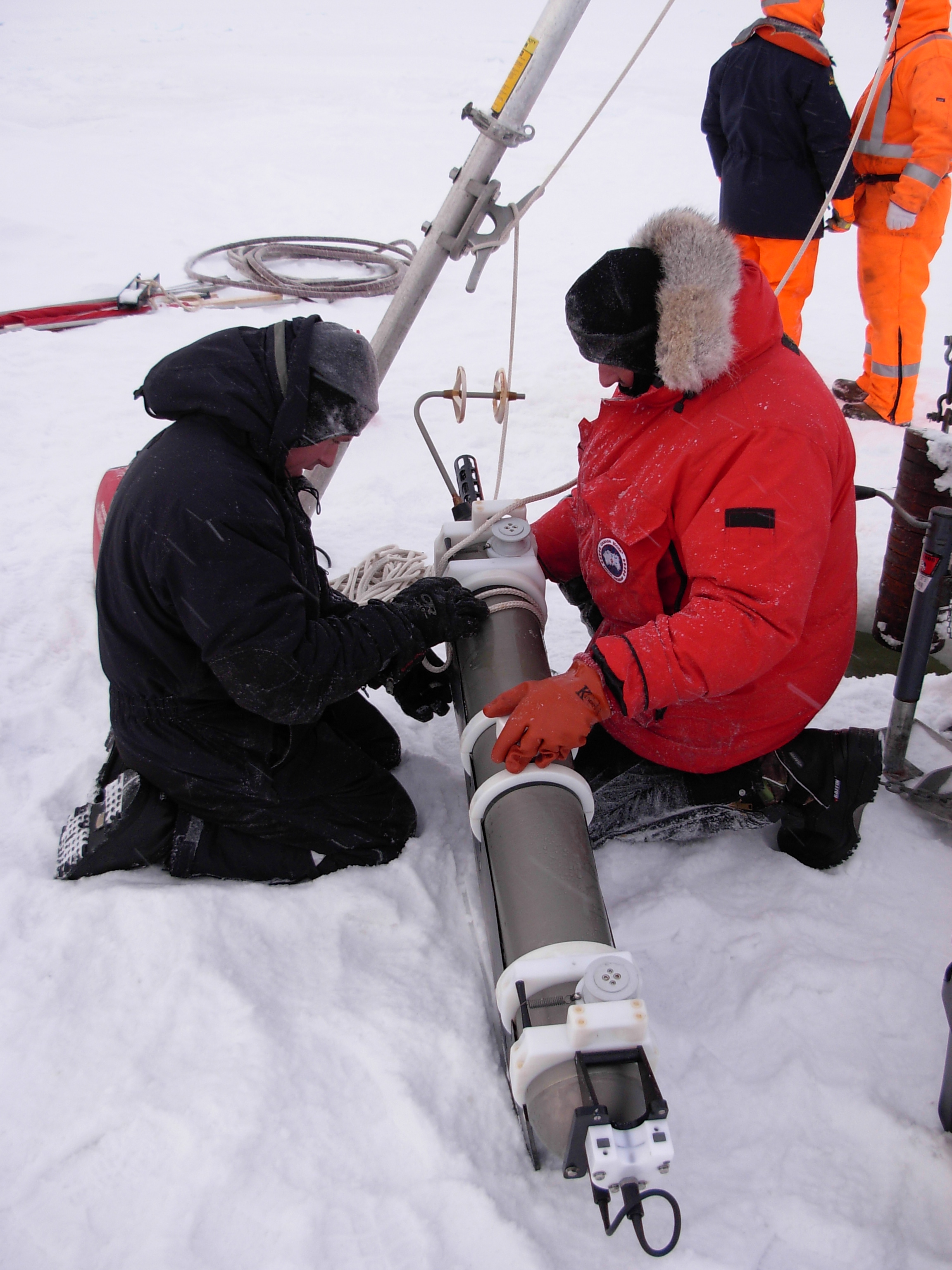

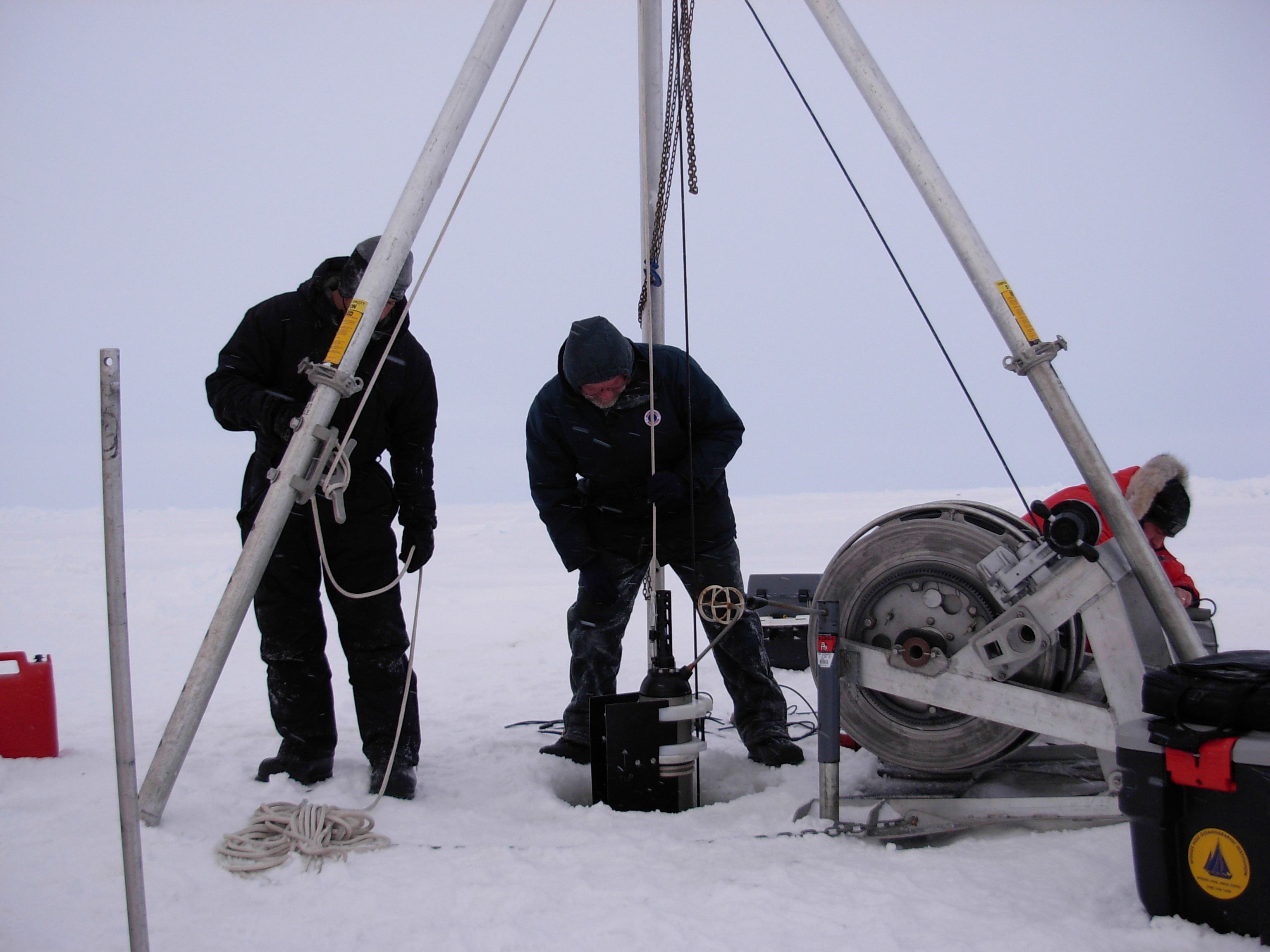

The final ITP deployment for JOIS 2010 was a prototype with a current probe with stabilizing fins which required a 24” diameter hole to be drilled through the floe. Time was running out on the cruise to find a decent ice floe for the deployment, as the ship was heading south, and would soon be out of the perennial ice zone. The days were also becoming increasingly shorter and the weather more winter-like.

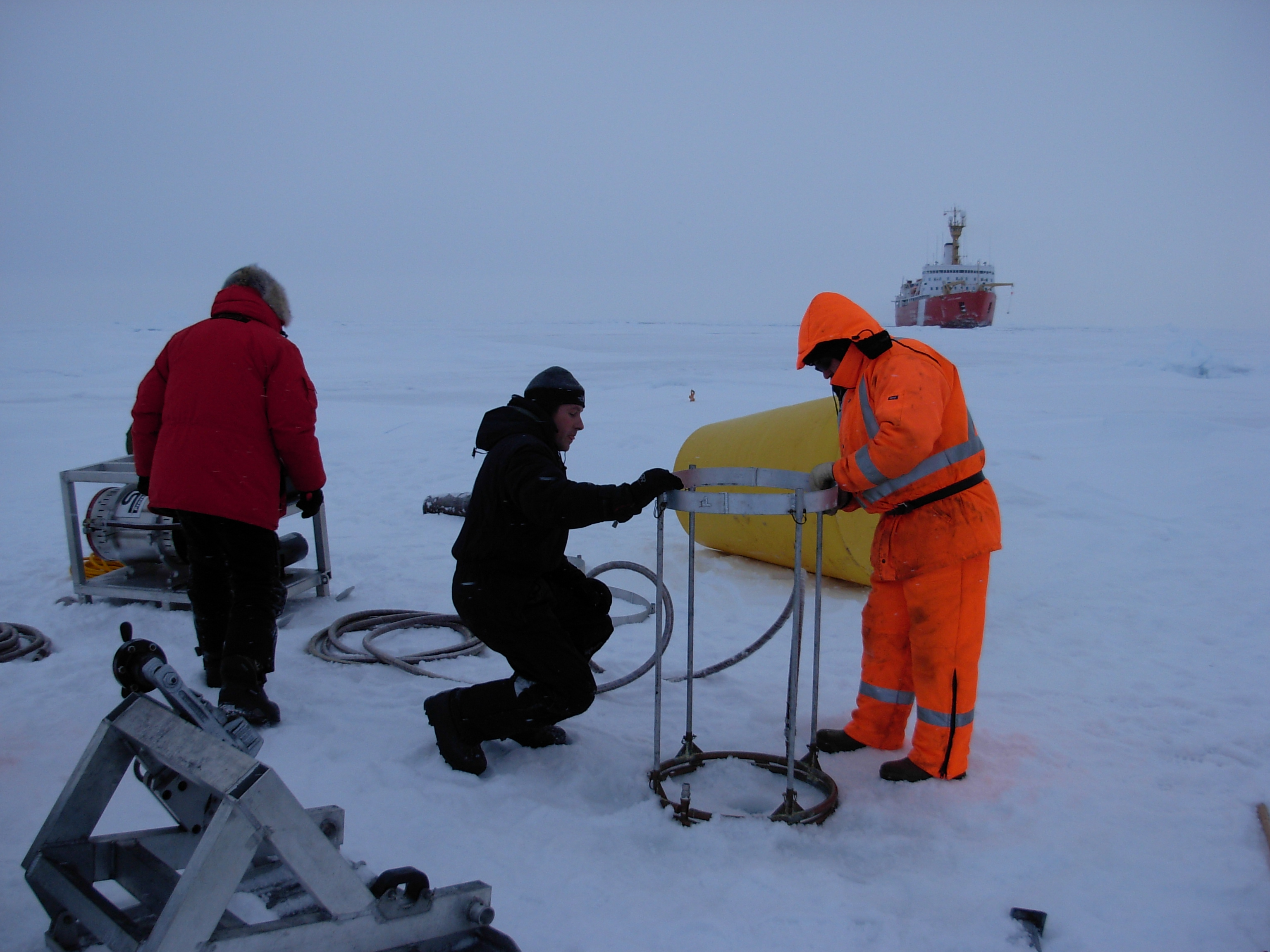

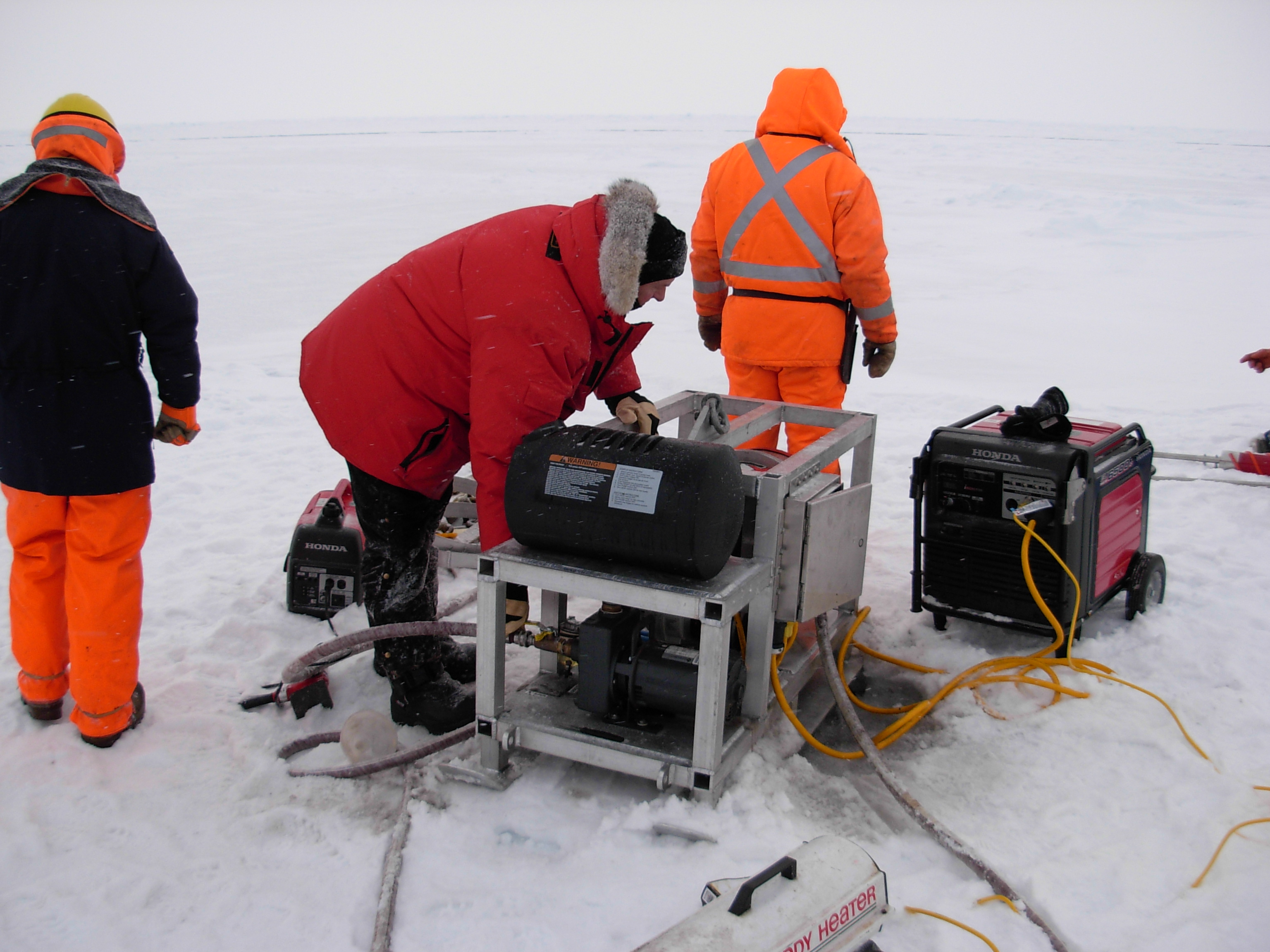

Consequently, the deployment team had to settle for a relatively tiny floe that was only 1.55 m thick. A portable hot water drill ring apparatus was used to melt through the floe, after some difficulty with frozen hoses in the sub-zero (< -5° C) conditions. The ice core was removed by cutting up the core with a chainsaw. The remainder of the deployment proceeded as usual, finishing with the surface flotation collar effectively corking the 2 foot hole. The backhauling of deployment apparatus and personnel was quickened due to the approaching darkness and bursts of snowfall.

More information and photos on the deployment operation are also available at: https://www.whoi.edu/page.do?pid=66818.