ITP 78 Deployment operations

On March 10, 2014, MIZ ice camp and runway (C3) were established for deployment of MIZ-C array including ITP 78. Because all of the deployment apparatus and associated handling equipment were left at C2, the ITP78 surface package, profiling instrument, surface floatation and anchor were the only items left back at Sachs Harbour. The Borek Twin Otter left early in the morning with personnel to site and setup the C3 camp location. This involved visually finding a suitable ice flow for both, a runway, and enough room to accommodate 2-3 tents and locations for buoys to be deployed. The team landed and did a 2” ice thickness survey to determine if the ice was thick enough to support multiple landings over the course of the project.

Once the flow was found, the remaining gear was loaded in the B.A.S plane (except the profiler which needed to be kept warm). The distance to C3 was roughly the same, but we had to land at C2 first to drop off two technicians to finish up with the AOFB deployment and also load as much of the gear left at C2 for the ITP78 and companion AOFB deployment. Two flights back and forth from C3 were required to transfer of the gear. The runway at C3 was much smoother and longer than C2 so getting on and off the flow went very well.

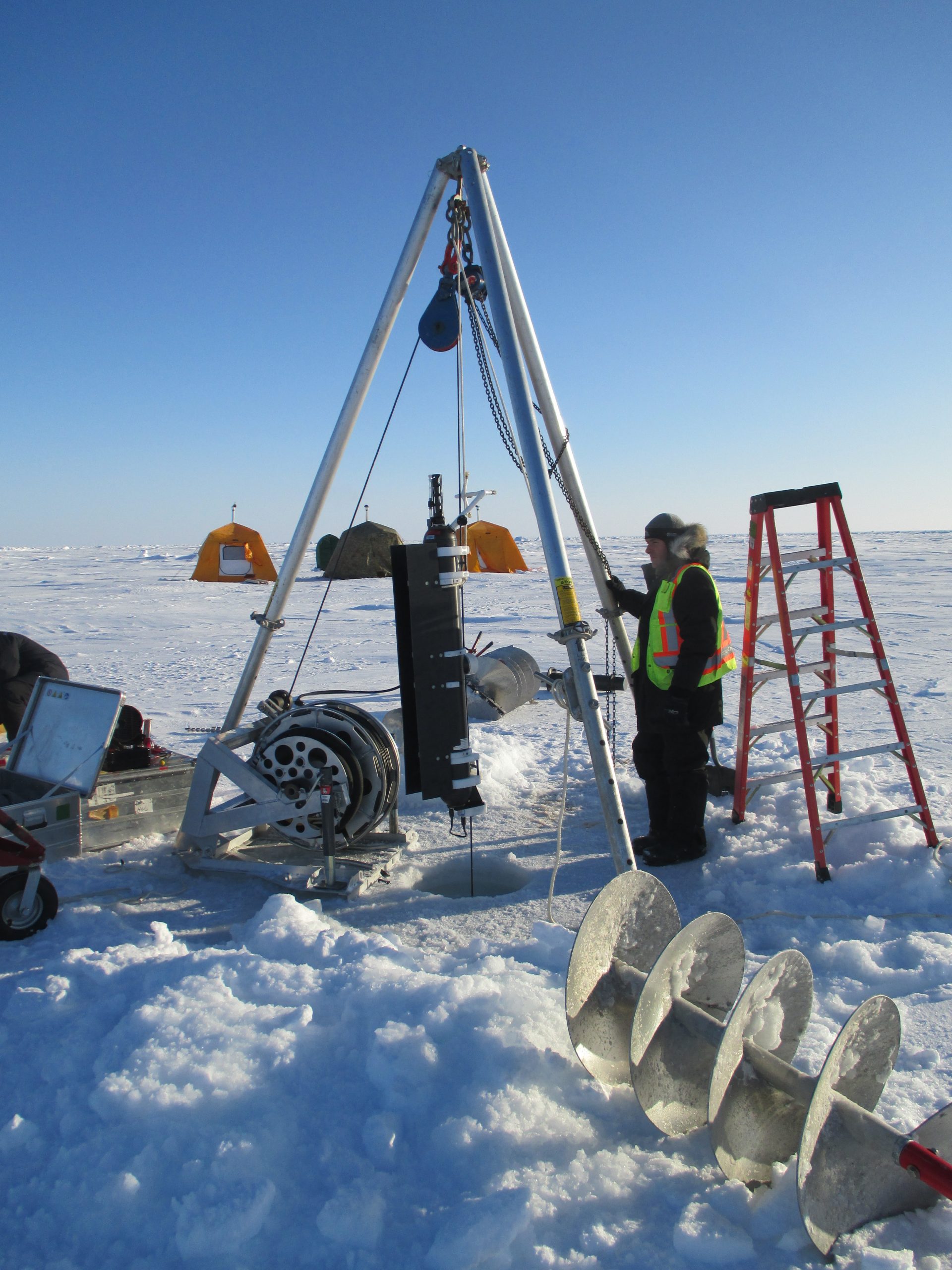

On March 11, the profiler was loaded on the Borek Otter at the airport and then headed directly to C2 to pick up the last remaining piece of gear. It was -40°C at C2 which was the coldest temperature recorded yet. The deployment for ITP 78 began upon return to C3. Starting with cutting the 24” hole for the ITP seemed to be the best way of doing things as this gave the AOFB time to be organized adjacent to our location. Although the temperature was above -40°C, it was still cold enough to make starting the hydraulic power pack difficult and the use of the battery charger necessary.

Once the profiler was in the water up to the CTD section, an IMM test was performed to confirm the connection. The wire rope was then deployed which took roughly 30 minutes. In the meantime, the gear needed for the AOFB deployment was staged at the deployment site to save time then the tripod and hydraulic setup was moved to the AOFB deployment location. Because there was more snow, the use of the Akio and Otter sleds were necessary. A was a bit windier for this deployment, so once the buoy was in the hole, a tent was setup and placed over the buoy in order to make the assembly of the top mast section easier and safer.