ITP64 Deployment Operations

After deploying ITPs (numbers 65 & 66) on ice stations the previous 2 days, limited ship time and limited ice floes required that ITP 64 be deployed over-the-side of the ship into open water near an ice edge. Deploying an ITP directly in the ocean is less preferable than on ice, since it may encounter significant wave motion which obstructs the profiler before the ice freezes around the buoy, and can decrease instrument durability. However, not having to stage an ice operation nor auger a hole through an ice floe saves a significant amount of deployment time.

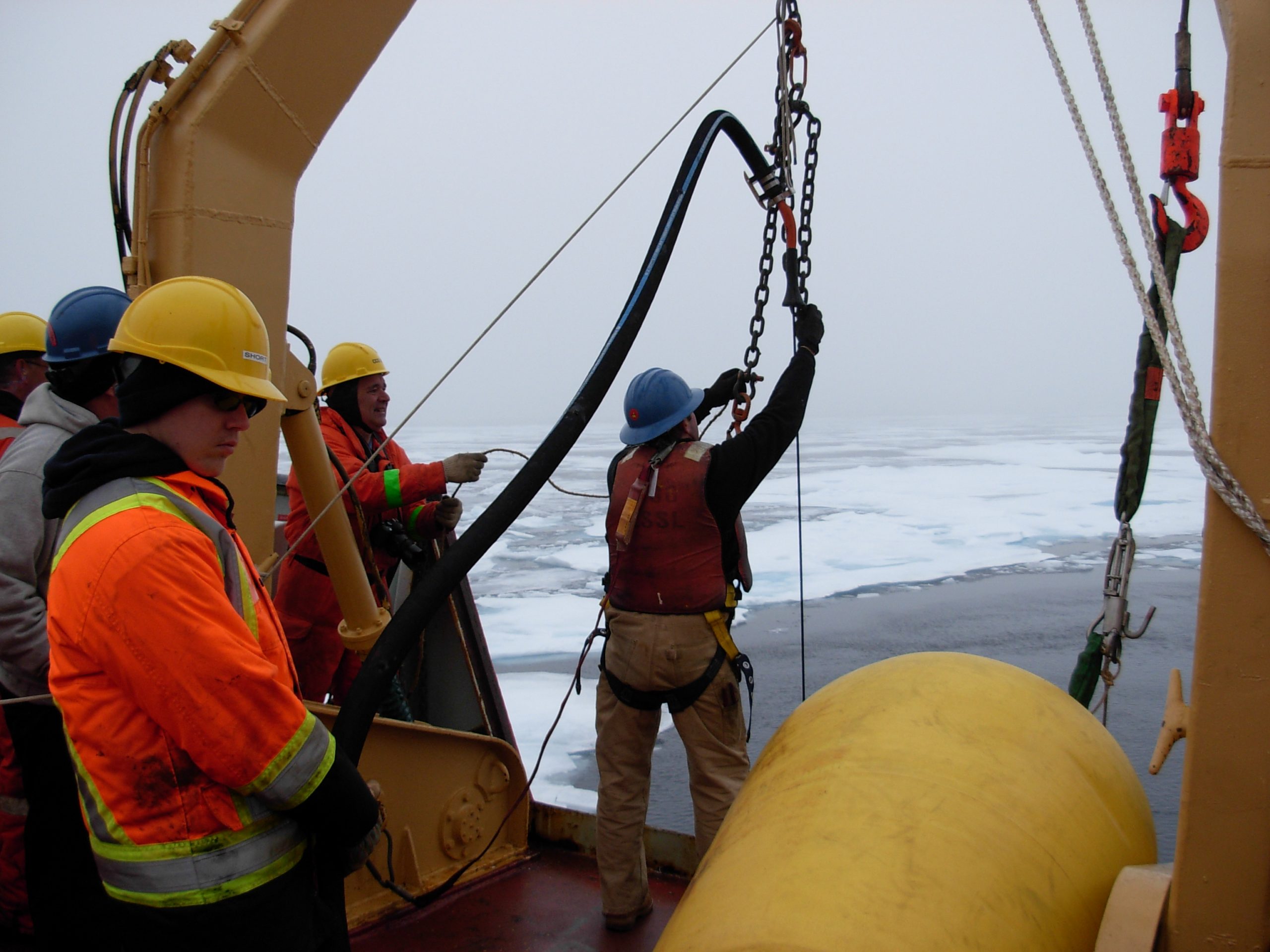

The ice nearby and lack of winds produced light fog for the deployment. The ITP buoy, wire, anchor and winch were moved from the helicopter staging area to the foredeck for the deployment which occurred using the starboard A-frame and crane. The same ITP deployment winch that would have been used on the ice was secured to the hydro winch bolted to the ship’s deck, and the wire fed through a block suspended from the A-frame.

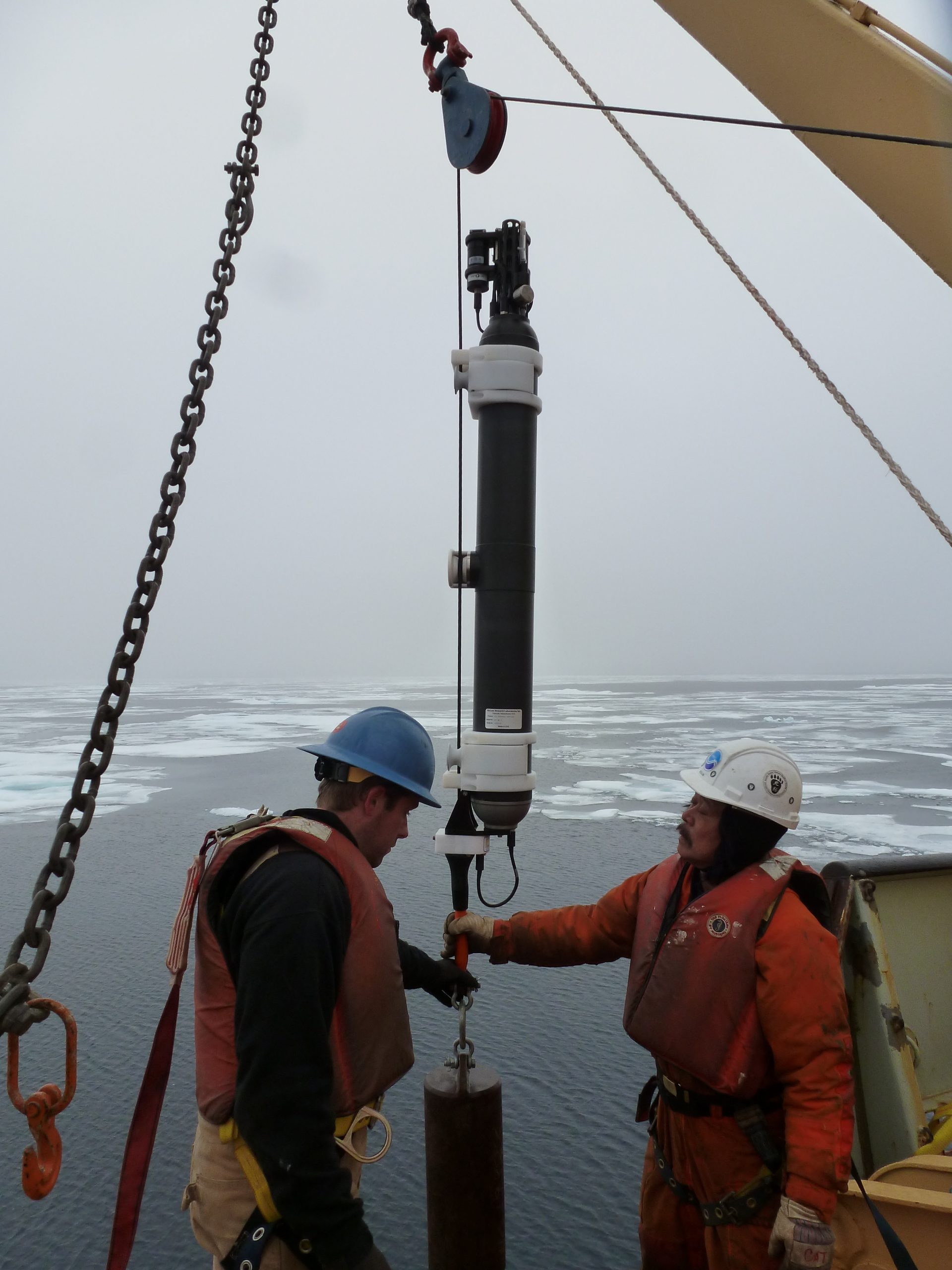

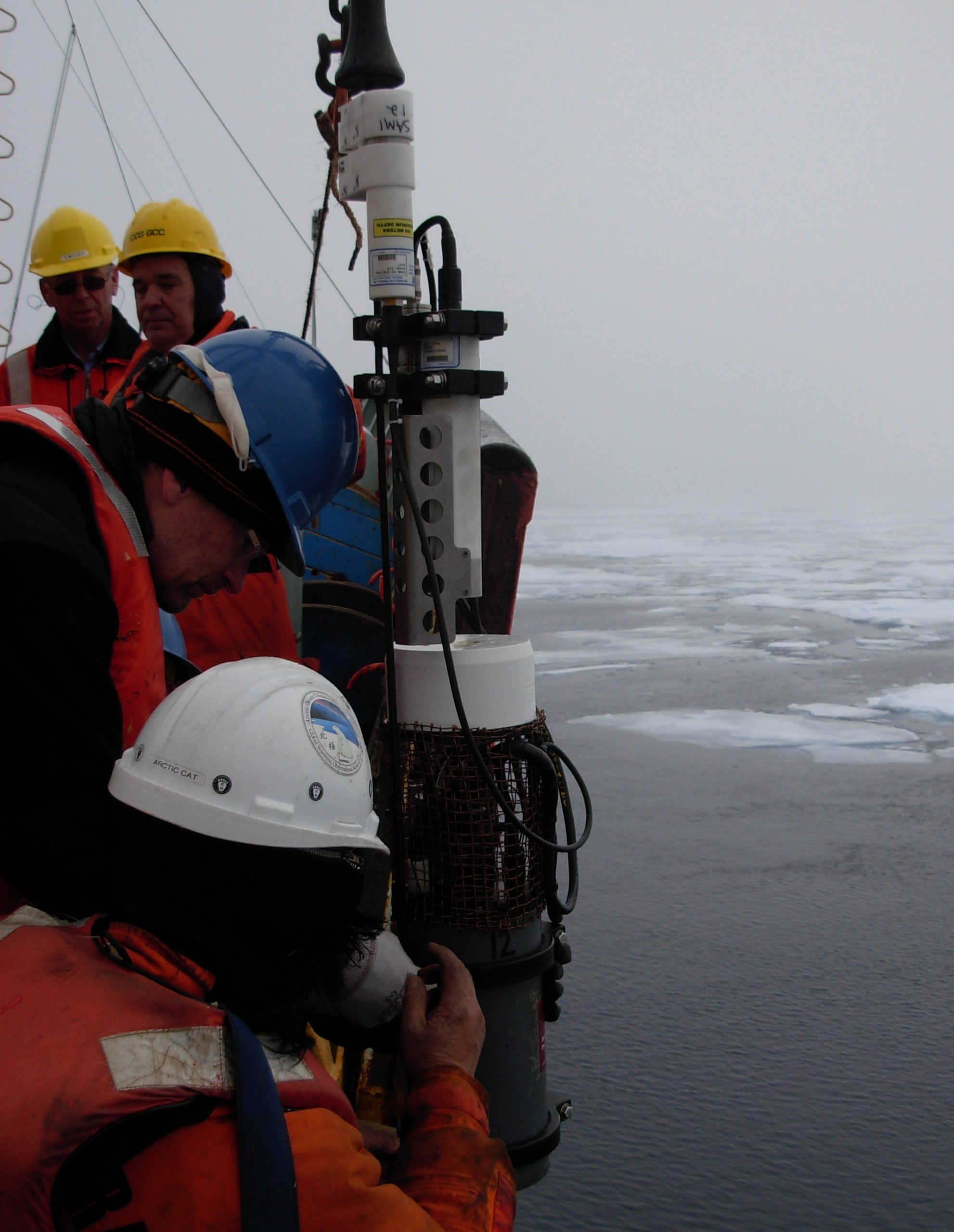

Light winds kept the ice away from the side of the ship during the deployment, and without the need to drill a hole in a floe, the ITP profiler could be lowered over-the-side on the bottom bumper on the wire above the anchor. The wire was unspooled using the winch brake in an hour, then the SAMI assembly consisting of SAMI pCO2, SBE 37 microcat and SBE inductive modem were clamped to the top the wire at ~6m, just below the potted section of cable and above a top bumper placed to mechanically prevent the ITP from profiling into the SAMI. Ten minutes later, the mooring was transferred to the buoy, and the system released into the Arctic.

More information and photos on the deployment operations are also available at: https://archives.whoi.edu/beaufortgyre/www.whoi.edu/page.do@pid=111517.html.