ITP 112 Deployment

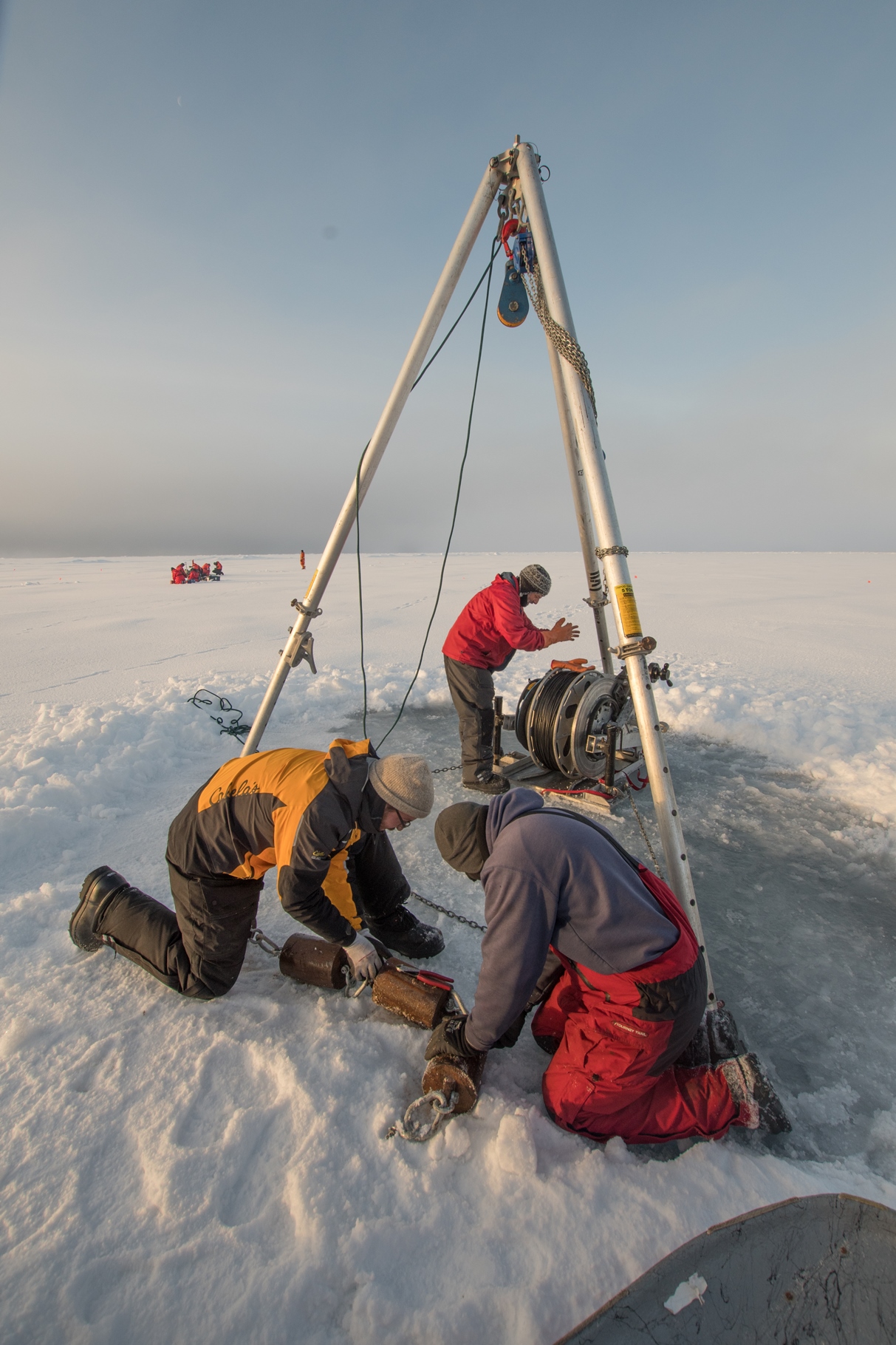

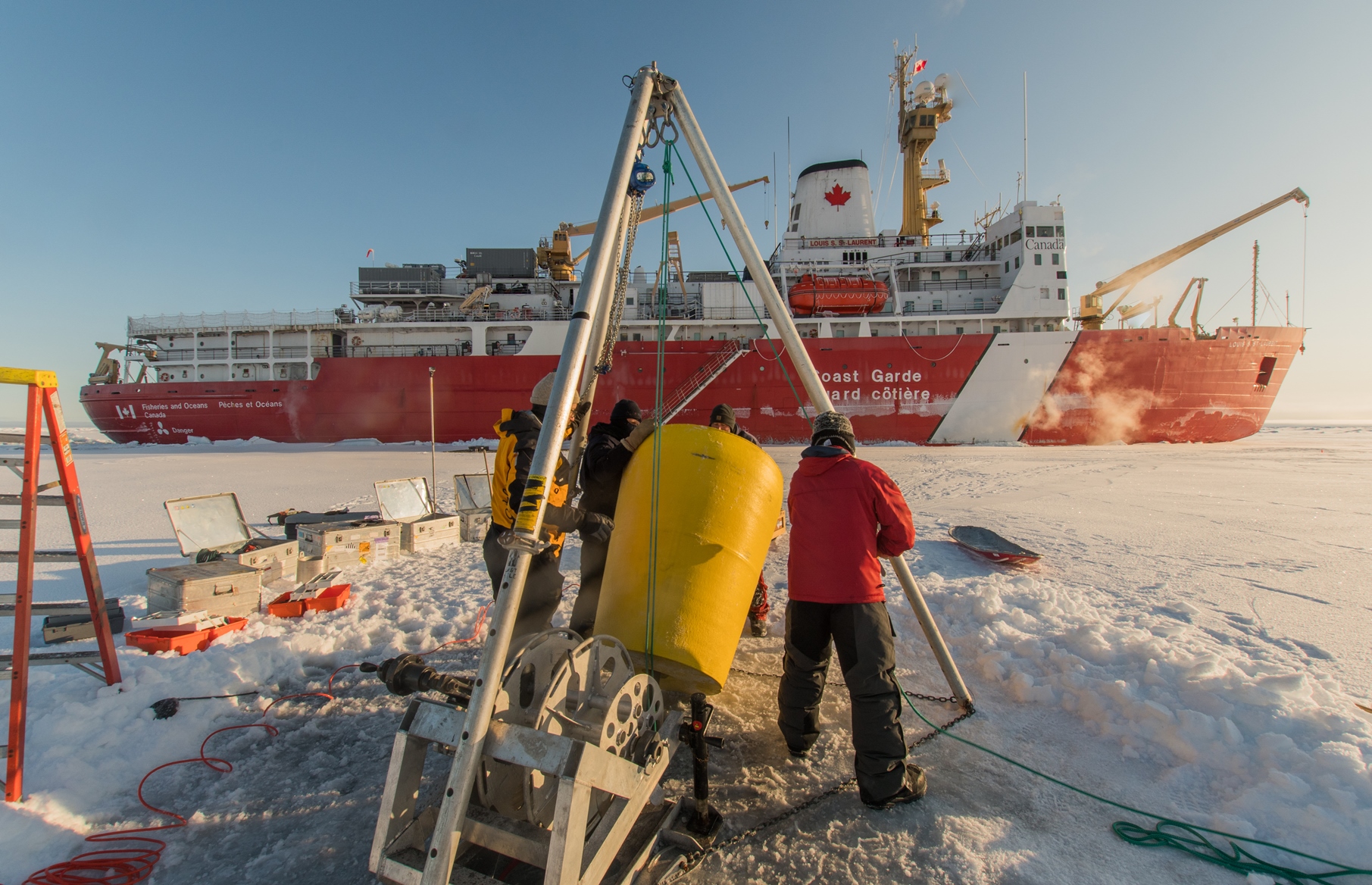

ITP 112 was the fourth ITP (third on an ice station) deployed during JOIS 2019. When drilling the deployment hole through the ice, it was found that the site was in an old melt pond (not detected during the original survey) with about 25cm of ice followed by a layer of water and more ice totaling 0.7 m of overall thickness. Gear was craned onto the ice, the winch was moved into place, tripod assembled, snatch block and chain fall attached and anchors assembled. The mooring wire was positioned and the anchors hoisted and lowered into the hole.

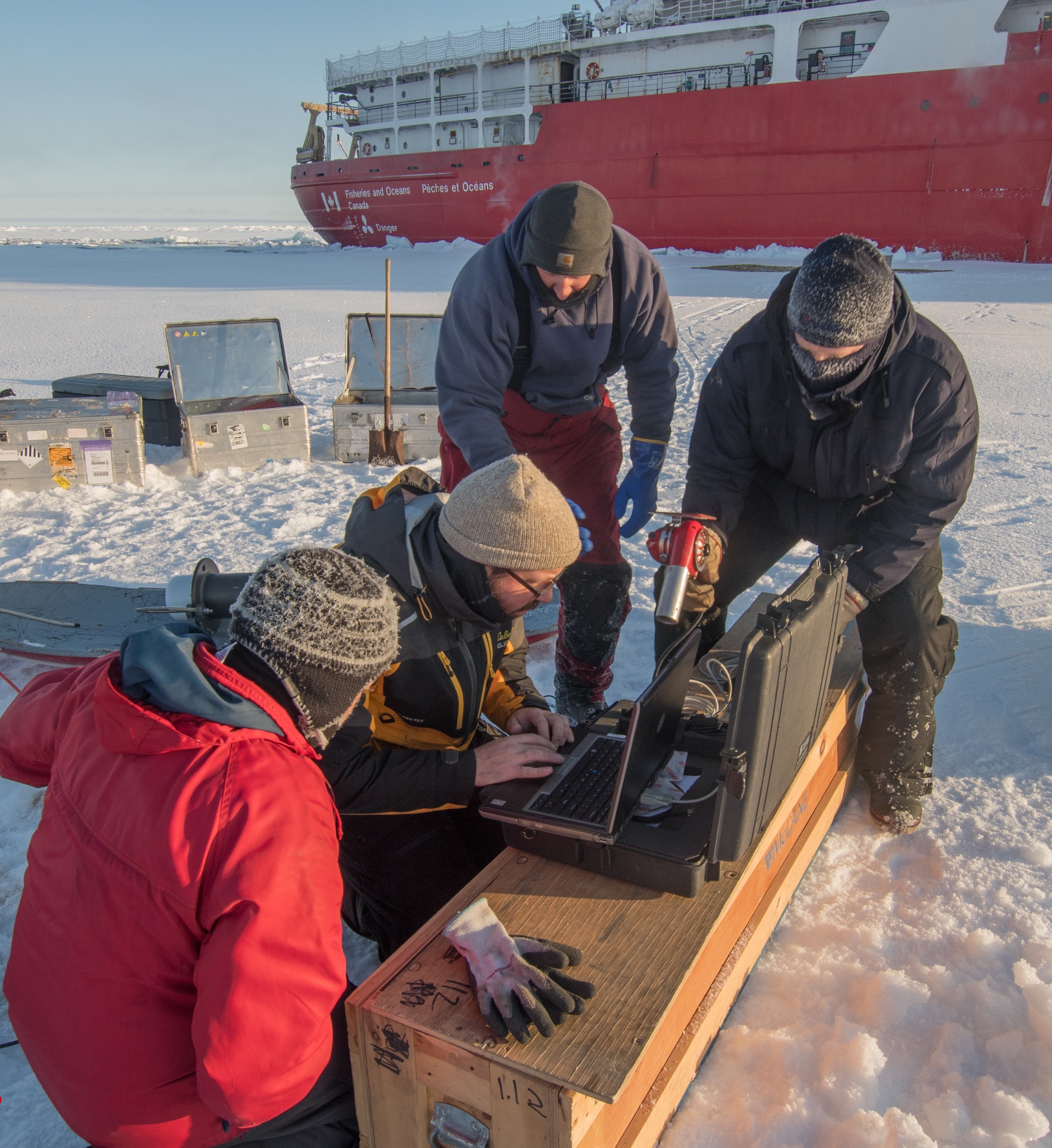

Thirty meters of wire was paid out and the ITP profiler suspended in the hole with a length of VLS rope and clove hitch up to a pear link and down to the cleat. A heat gun was used to warm up all of the connectors and bulkheads on both the potted section and the surface package. The temporary grounding plate was hooked up and placed in the water and the 4pin jumper was run from the potted section to the surface package. The surface package was woken and the test script was run so that communication between surface and profiler was confirmed. These cables were removed and everything was secured to continue paying out wire rope. The clove hitch and VLS was removed from profiler and the wooden handle of the shovel was used to shove the ITP down through the ice hole.

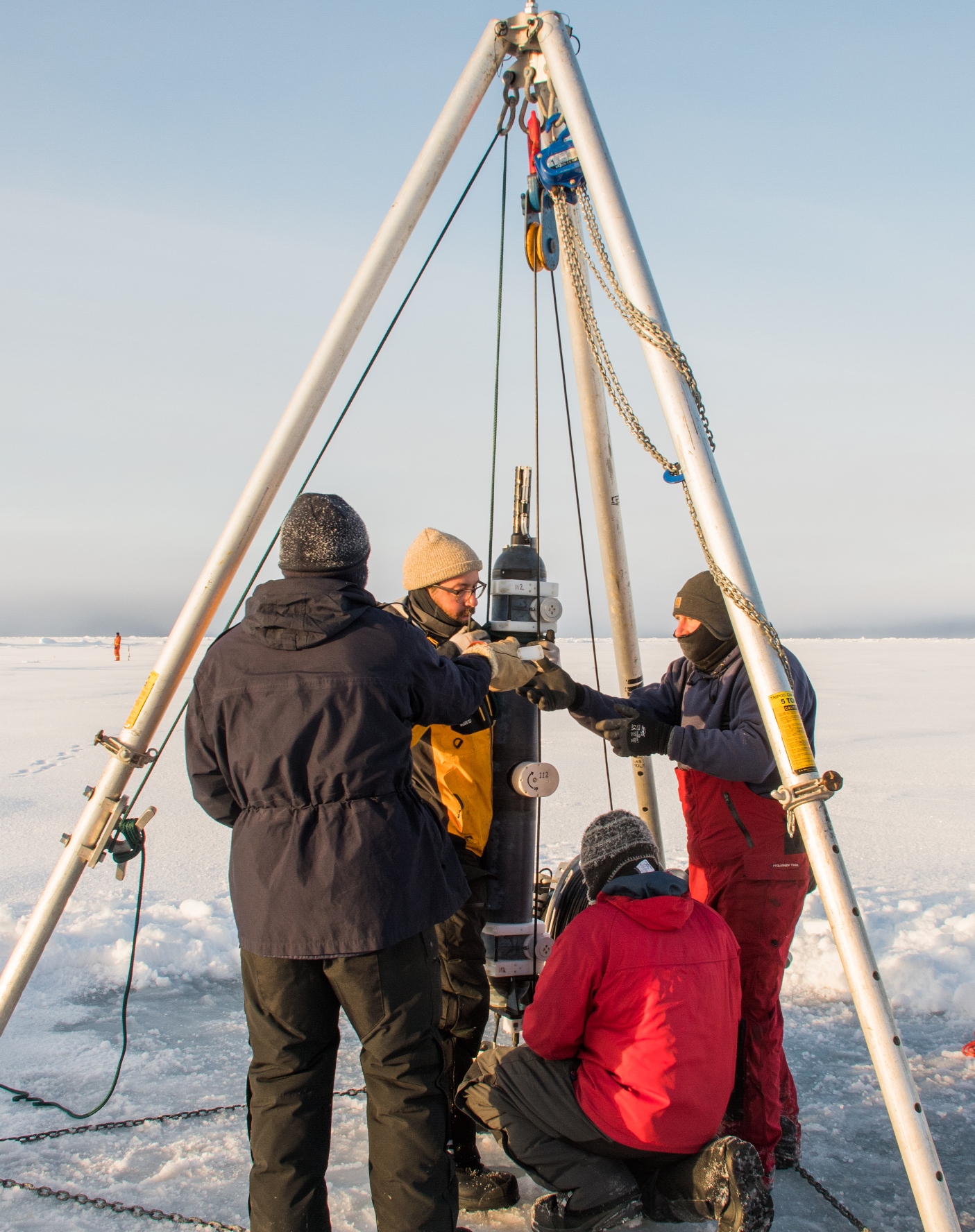

Wire was paid out until approximately 10 wraps remained on the reel. A Yale grip was applied to the mooring wire and load was transferred to the chain fall. Wire was removed from the snatch block and snatch block was removed from the tripod. The remaining wire was walked off through the ‘front’ of the tripod and slightly off to one side as the ITP upper potted section was removed from the reel. The potted section was fed through the bottom of surface package flotation and assembled to bottom of surface package and grounding plate and bail were assembled to lower potted section at the same time. The surface package was placed in the foam and the foam dragged towards the hole. The VLS slip line was attached to the bail on the potted section and the bail end of the potted section was hauled up above the Yale grip and secured to the cleat. The remaining wire was slipped through the Yale grip until the load was transferred to the potted section bail and slip line. The Yale grip was removed and the potted section was slipped into the hole until the foam was upright. A final inductive modem check was completed and the inductive modem cable dummied off and stuffed into the foam and the installation was complete.

Ice analyses were also performed by others in the science party while the IBO deployment operations took place.

More information and photos on the deployment operations are also available at: https://archives.whoi.edu/beaufortgyre/www.whoi.edu/page.do@pid=165416.html

Recovery